Mohala oa tlhahiso ea lisekoere tsa lisekoere tse 10-20L tse iketsang

Mohala oa tlhahiso ea lisekoere tsa lisekoere tse 10-20L tse iketsang

Likarolo tse ka Sehloohong

1. Phihlelo le botumo ba lilemo tse fetang 20 lapeng le kantle ho naha;

2. Tiisetso ea Boleng, e ntle ka mor'a tšebeletso le theko e utloahalang;

3. E tšepahala ebile e bolokehile ho e laola, e bonolo ho e sebelisa le ho e hlokomela;

4. E na le sebopeho sa khomphutha sa motho le PLC; amohela theknoloji ea taolo ea dijithale;

5. Hlobo e feletseng e iketsang, e etsang halofo ea othomathiki, le e mengata, e loketse libopeho le boholo bo fapaneng ba makotikoti.

Big lisekoere ka othomathiki tlhahiso ea mola tshebetso ya ho sebetsa

Taba ea pele, beha thepa ea 'mele ea thini e khaotsoeng tafoleng ea ho fepa ea mochini oa ho tjheseletsa o iketsang, u monye ka har'a li-sucker tsa vacuum, u romele likheo tsa thini ho rolara ea ho fepa ka bonngoe. Ka rolara ea ho fepa, thini e le 'ngoe e se nang letho e fepeloa ho rolara ea ho potoloha ho etsa ts'ebetso ea ho potoloha, ebe e fepeloa ho mokhoa oa ho etsa ho potoloha ho etsa ho potoloha.

'Mele o fepuoa ka har'a mochini oa ho tjheseletsa o hanyetsang 'me o etsoa ho tjheseletsa ka mor'a ho beha hantle. Kamora ho tjheseletsa, 'mele oa nkho o fepuoa ka bohona ka har'a sesebelisoa sa makenete se potolohang sa mochini oa ho tjheseletsa bakeng sa ho roala ka ntle, ho roala ka hare kapa ho roala ka hare ho phofo, e leng se itšetlehileng ka litlhoko tse fapaneng tsa moreki. E sebelisoa haholo-holo ho thibela mola oa seam oa lehlakoreng ho pepesehela moea le mafome. 'Mele oa nkho o lokela ho beoa ka ontong ea ho omisa ka induction hore o ome haeba e le roala ka hare kapa roala ka hare ho phofo. Kamora ho omisa, e tla fepuoa sesebelisoa sa ho pholisa ho etsa pholiso ea tlhaho.

Mmele oa nkho o pholileng o fetisetsoa mochining o moholo oa motsoako oa nkho, 'me 'mele oa nkho o boemong bo otlolohileng o feta ka har'a conveyor e otlolohileng. O fetisetsoa seteisheneng sa pele sa ho kenya seam se othomathiki ka ho iketsa ka li-clamp. Seteishene sa bobeli se atoloha ka sekwere. Ha 'mele oa nkho o le boemong ba oona, tereing ea ho phahamisa 'mele oa nkho e laoloang ke enjene ea servo, 'me 'mele oa nkho o romeloa ke tereing ena ea ho phahamisa hlobong e atolohang ea sekwere ho etsa hore ho atolohe sekwere. Seteishene sa boraro ke ho etsa ho khabisa phanele le sekhutlo.

Ha mmele wa kane o le boemong ba wona, hodima terei ya ho phahamisa mmele wa kane e laolwang ke enjene ya servo, mme mmele wa kane o romelwa ke terei ena ya ho phahamisa ho ya ho panele ya ho etsa le ho betla dikhutlo ka nako e le nngwe. Seteishene sa bone se flanging hodimo, seteishene sa bohlano se flanging hodimo. Ho flanging ho tlase: kane e tla romelwa hlobo e flanging hodimo e rapameng karolong e ka hodimo ya mochini ka ho phahamisa terei ho e etsa. Ho flanging hodimo: silindara e ka hodimo e tla hatella mmele wa kane ho ya boemong ba hlobo e flanging hodimo ho e etsa.

Ho phunya ha 'mele oa thini e ka holimo le e ka tlase ho tsamaisoa ka lisilindara tse 'ne. Seteishene sa botšelela se lemoha le ho fepa le ho roka sekoahelo ka boiketsetso. Kamora mekhoa e tšeletseng e boletsoeng ka holimo, thini e tla khutlisetsoa morao holimo le tlase ka sesebelisoa sa ho kgutlisa morao, ebe e etsa ho roka holimo, ts'ebetso ena e tšoana le ts'ebetso ea ho roka tlase. Qetellong, thini e felileng e fepeloa ke conveyor ho ea seteisheneng sa ho leleka ka boiketsetso. Kamora tlhahlobo e nepahetseng ea mohloli oa moea, lihlahisoa tse sa tšoanelehang lia fumanoa 'me li sutumelletsoa sebakeng se tsitsitseng, 'me lihlahisoa tse tšoanelehang li tla tla bencheng ea mosebetsi ea ho paka bakeng sa ts'ebetso ea ho qetela ea ho paka.

Likarolo tse entsoeng ka tšepe ena li ka etsa mola

| Bophara ba pele ba ho seha/bonyane | 150mm | Bophara ba bobeli ba ho seha/bonyane ba metsotso | 60mm |

| Lebelo /likhomphutha/metsotso | 32 | Botenya ba lakane | 0.12-0.5mm |

| Matla | 22KW | Palo ea li-volts | 220v 380v 440v |

| Boima ba 'mele | 21100kg | Tekanyo ea Mochini | 2530X1850X3990mm |

Moleng o tloaelehileng oa tlhahiso ea canbody, slitter ke mohato oa pele ts'ebetsong ea tlhahiso. E seha maqephe a tšepe a hatisitsoeng le a koahetsoeng ka lacquer hore e be libaka tse se nang letho tsa 'mele tsa boholo bo hlokahalang. Ho eketsoa ha yuniti ea phetisetso ea stack e se nang letho ho eketsa katleho ea slitter.

Li-slitter tsa rona li entsoe ka mokhoa o ikhethileng. Li tiile haholo, li nolofalletsa phetoho e bonolo le e potlakileng mefuteng e fapaneng e se nang letho 'me li netefatsa ho nepahala ho phahameng haholo. Ha ho tluoa tabeng ea ho feto-fetoha ha lintho, ho nepahala, ho tšepahala le lebelo la tlhahiso, li-slitter tsa rona li loketse haholo tlhahiso ea makotikoti a thini.

| Mohlala oa mochini | CTPC-2 | Motlakase le Maqhubu | 380V 3L+1N+PE |

| Lebelo | 5-60m/motsotso | Tšebeliso ea phofo | 8-10mm & 10-20mm |

| Tšebeliso ea moea | 0.6Mpa | Sebaka sa bophara ba kariki | D50-200mm D80-400mm |

| Tlhokahalo ea moea | 100-200L/motsotso | Tšebeliso ea matla | 2.8KW |

| Litekanyo | 1090*730*1830mm | Boima ba 'mele | 310kg |

Sistimi ea ho koahela phofo ke e 'ngoe ea lihlahisoa tsa ho koahela phofo tse qalileng ke Khamphani ea Changtai. Mochini ona o nehetsoe theknoloji ea ho koahela ka spray ea li-weld tsa litanka tsa bahlahisi ba makotikoti. Khamphani ea rona e sebelisa theknoloji e tsoetseng pele ea ho koahela phofo, e etsang hore sebopeho se secha sa mochini se be se setle, ts'epahalo e phahameng ea sistimi, ts'ebetso e bonolo, ts'ebeliso e pharaletseng le karolelano e phahameng ea ts'ebetso le theko. Le ts'ebeliso ea likarolo tse tšepahalang tsa taolo, le terminal ea taolo ea ho ama le likarolo tse ling, e leng se etsang hore sistimi e be e tsitsitseng le e tšepahalang haholoanyane.

| Sebaka sa maqhubu | 100-280HZ | Lebelo la ho tjheseletsa | 8-15m/motsotso |

| Bokhoni ba tlhahiso | 25-35Makoti/motsotso | Bophara ba kotikoti bo sebetsang | Φ220-Φ300mm |

| Bophahamo ba thini e sebetsang | 220-500mm | Lintho tse sebetsang | Poleiti ea tšepe, e thehiloeng tšepeng, Poleiti ea Chrome |

| Botenya ba thepa bo sebetsang | 0.2 ~ 0.4mm | Bophara ba terata ea koporo e sebetsang | Φ1.8mm ,Φ1.5mm |

| Metsi a pholileng | Mocheso: 12-20℃ Khatello:> 0.4Mpa Phallo: 40L/min | ||

| Matla ohle | 125KVA | Tekanyo | 2200*1520*1980mm |

| Boima ba 'mele | 2500Kg | Phofo | 380V±5% 50Hz |

Motjhini oa ho tjheseletsa oa canbody ke oa bohlokoa moleng ofe kapa ofe oa tlhahiso ea makotikoti a likarolo tse tharo. O etsa hore 'mele o be le lesoba sebopehong sa ona sa mantlha mme o tjheseletsa ho kopana ha seam. Molao-motheo oa rona oa ho tjheseletsa oa Superwima o hloka ho kopana ho fokolang feela ha likarolo tse 'maloa tsa leshome tsa millimeter. Taolo e ntle ea hona joale ea ho tjheseletsa e kopantsoe le khatello e lumellanang hantle le ho kopana ha ho kopana. Ho tloha ha ho qalisoa moloko o mocha oa batjhini ba ho tjheseletsa, bareki lefatšeng ka bophara kajeno ba tiisitse khotsofalo ea bona e kholo mabapi le ts'epo e ikhethang le e phahameng ea mochini hammoho le tlhahiso e theko e tlaase le e sebetsang hantle. Litekanyetso tse ncha tsa indasteri li se li behiloe tlhahisong ea makotikoti lefatšeng ka bophara.

| Bophahamo ba kan bo sebetsang | 50-600mm | Bophara ba kan bo sebetsang | 52-400mm |

| Lebelo la rolara | 5-30m/motsotso | Mofuta oa ho roala | Seaparo sa roller |

| Bophara ba lacquer | 8-15mm 10-20mm | Phepelo e ka sehloohong le mojaro oa hona joale | 220V 0.5 KW |

| Tšebeliso ea moea | 0.6Mpa 20L/motsotso | Tekanyo ea mochini & | 2100*720*1520MM300kg |

Mochini o koahelang phofo ke karolo ea bohlokoa ea mohala oa tlhahiso ea makotikoti a likarolo tse tharo, o rorisoang haholo ke bareki lapeng le kantle ho naha 'marakeng' me ke sesebelisoa se setle sa ho etsa makotikoti. Chengdu Changtai e ikemiselitse ho fa bareki lisebelisoa tsa ho etsa makotikoti tsa boleng bo holimo le ho nts'etsapele tharollo e ntle ka ho fetisisa.

| Lebelo la conveyor | 5-30m/motsotso | Sebaka sa bophara ba kariki | 52-180mm |

| Mofuta oa conveyor | Seteishene sa ketane se bataletseng | Khoele ea ho pholisa. | Ha e hloke metsi/moea |

| Ho futhumatsa hantle | 800mm*6(30cpm) | Phepelo e ka sehloohong | 380V+N>10KVA |

| Mofuta oa ho futhumatsa | Tlhahiso | Sebaka sa ho lemoha | 5-20MM |

| Ho Futhumatsa ho Hoholo | 1KW*6 (sete ea mocheso) | Ntlha ea tlhahiso | 40MM |

| Seta sa maqhubu | 80KHz+-10 KHz | Nako ea tlhahiso | 25Sec(410mmH,40CPM) |

| Electro.Mahlaseli a sireletsang | E koahetsoe ke balebeli ba tšireletso | Nako ea ho phahama (MAX) | Sebaka 5mm 6sec & 280℃ |

| Ho fokotseha ha maikutlo | 6300*700*1420mm | Boima bo kahare | 850KG |

Changtai e na le mefuta e fapaneng ea litsamaiso tsa ho lokisa tse etselitsoeng ho thatafatsa lera la tšireletso ea moalo ka katleho. Hang ka mor'a ho sebelisa lera la tšireletso ea moalo oa lacquer kapa phofo, canbody e ea kalafong ea mocheso. Re ntlafalitse litsamaiso tsa ho futhumatsa tse tsoetseng pele tse tsamaisoang ke khase kapa induction tse nang le taolo ea mocheso o iketsang le mabanta a conveyor a fetoloang lebelo. Litsamaiso ka bobeli tsa ho futhumatsa li fumaneha ka sebopeho sa mola kapa sa U.

Mochini o kopanyang 'mele oa kariki o iketsang

| Bokhoni ba tlhahiso | 30-35cpm | Mefuta e fapaneng ea likoti tsa Dia | 110-190mm |

| Bolelele ba thini | 110-350mm | Botenya | ≤0.4 |

| Matla ohle | 26.14kw | Khatello ea tsamaiso ea pneumatic: | 0.3-0.5Mpa |

| Boholo ba conveyor e emisitsoeng ea 'mele | 2350*240*930mm | Boholo ba conveyor bo kentsweng | 1580*260*920mm |

| Boholo ba mochini o kopantsoeng | 2110*1510*2350mm | Boima ba 'mele | 4T |

| Boholo ba khabinete ea motlakase | 710*460*1800mm | ||

Mohala oa tlhahiso ea makotikoti hangata o fella ka palletizer. Mohala oa kopano ea lipane o ka fetoloa hore e be oa hau, e leng se tla netefatsa hore ho na le li-stack tse ka kenngoang palleting mehatong e latelang.

Mohala oa tlhahiso ea lithini tse potolohang ka boiketsetso

Mohala oa tlhahiso ea nkho o loketse tlhahiso ea kane ea lisekoere ea 10-20L ka boiketsetso, e entsoeng ka lipoleiti tse tharo tsa tšepe: 'mele oa nkho, sekoahelo le karolo e ka tlase ea nkho. Nkho e bōpehile joaloka lisekoere.

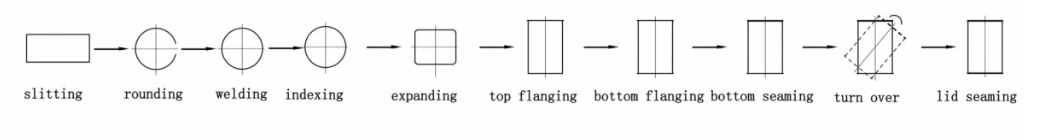

Phallo ea tekheniki: ho seha lakane ea thini ho isa ho se nang letho-ho potoloha-ho tjheseletsa-ka hare le ka ntle

(sekoahelo sa phofo ea ka hare le sekoahelo sa kantle)-phanele e atolosang e omisang-e pholisang, e nang le lisekoere tse kholo,

sekhutlo se khabisitsoeng-sekoahelo se ka holimo se phaphametseng-sekoahelo se ka tlase se phaphametseng-sekoahelo se fepang-se phuthelang-se phetla-

tlhahlobo ea ho kenya sekoahelo se ka holimo, ho seha, ho lutla ha metsi