Mochini oa ho tjheseletsa oa Tin oa 200-401 oa tlhahiso ea lithini tsa 170ml-2.5L

Mochini oa ho tjheseletsa oa Tin oa 200-401 oa tlhahiso ea lithini tsa 170ml-2.5L

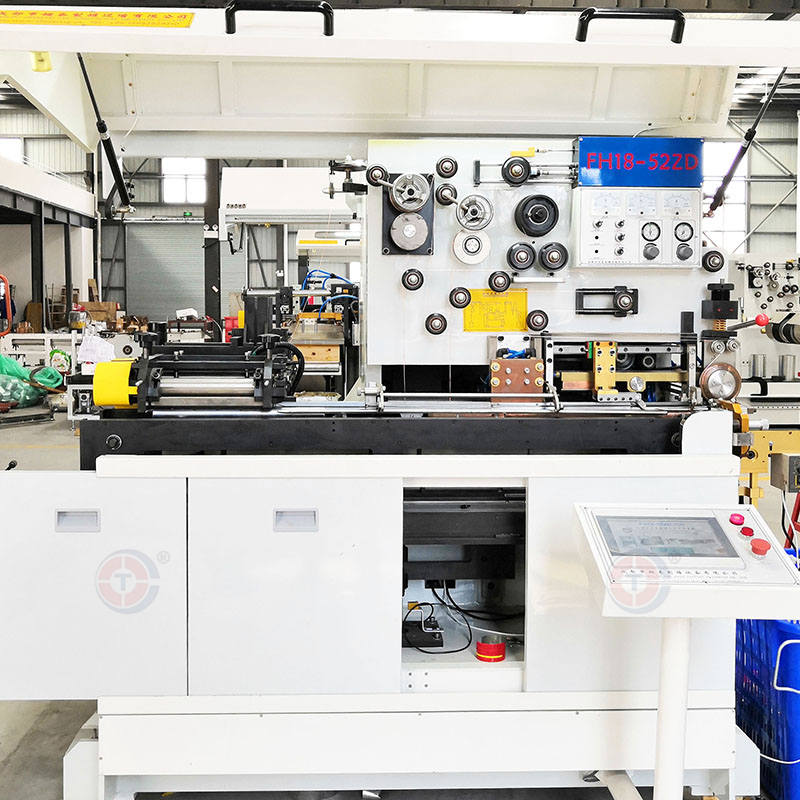

Mochini oa pele oa canbody: Mochini oa ho tjheseletsa can

Mochini oa ho tjheseletsa makotikoti ke eng?

Mochini oa ho tjheseletsa kane, oo hape o bitsoang mochini o tjheseletsang kane, mochini o tjheseletsang kane kapa moetsi oa 'mele oa ho tjheseletsa, Mochini o tjheseletsang kane ke oa bohlokoa moleng ofe kapa ofe oa tlhahiso ea makotikoti a likarolo tse tharo. Kaha mochini o tjheseletsang kane o nka tharollo ea ho tjheseletsa e hanyetsanang le mokhabiso oa lehlakore, o boetse o bitsoa mochini o tjheseletsang kane kapa mochini o tjheseletsang kane.

Kopo

Mochini oa ho tjheseletsa ka thini o sebelisetsoa ho monya le ho phutholla likheo tsa 'mele oa thini, ka har'a Z-bar ho laola ho kopana ha tsona, le ho tjheseletsa likheo joalo ka 'mele oa thini, o boetse o bitsoa welder kapa moetsi oa 'mele oa welding. Hobane welder ea 'mele oa thini e sebelisa tharollo ea ho tjheseletsa ea ho hanyetsa ho weld side seam, e boetse e bitsoa welder kapa side seam welding. Welder ea canbody e ka hokela mochining oa ho roala seam ka letsoho le ka tlase, ebe likheo tse tsoang mochining oa welding oa canbody li tla tsamaisoa ka ho otloloha le ka thelelo. Mochini oa welding oa tšepe o sebelisoa haholo bakeng sa lijana tsa tšepe tsa boholo bo fapaneng ka ho fetola yuniti ea ho lekanya, ebe welder ea thini e tenyetseha ebile e sebelisoa haholo.

Lintlha tse khutšoanyane mabapi le Mochini ona oa ho Tjhesetsa Makoti a Tin

Thipa ea ho seha terata ea koporo ea mochini e entsoe ka thepa ea motsoako e nang le bophelo bo bolelele haholo ba ts'ebeletso.

E bonolo ebile e hlakile bakeng sa sebopeho sa ts'ebetso ea skrine ea ho ama. Mochini oa rona o na le mehato e fapaneng ea tšireletso. Ha ho na le phoso, mechini e tla bontšoa ka bo eona skrineng ea ho ama 'me e khothalletsoe ho e sebetsana le eona. Lintlha tsa ho kenya le ho ntša tsa logic controller (PLC) tse ka hlophisoang li ka baloa ka kotloloho skrineng ea ho ama ha ho ntse ho hlahlojoa motsamao oa mochini,.

Ho otloa ha tafole ea ho welder ke 300mm, 'me karolo e ka morao ea welder e na le tafole, e ka kenngoang ka forklift, e leng se fokotsang nako ea ho eketsa tšepe. Ho seha ho chitja ho amohela mofuta oa ho hula, boholo ba ho seha ba lakane ea tšepe bo tlase, ha ho hlokahale hore ho lokisoe foreimi ea thepa ea mochini o chitja oa ho seha ho fetola mofuta oa pitsa.

Tanka ea ho fepa e entsoe ka tanka e kopantsoeng ea tšepe e sa hloekang. Phetoho e potlakileng ea mofuta oa tanka. Bophara bo bong le bo bong bo fanoa ka kanale e tsamaellanang ea ho tsamaisa tanka. U hloka feela ho tlosa likurufu tse peli, ho tlosa sekotjana sa tanka sa seteishene sa ho tsamaisa tanka, ebe u kenya sekotjana se seng sa tanka, e le hore phetoho ea mofuta oa tanka e nke metsotso e 5 feela.

Mabone a LED a behiloe ka pele ho mochini le ka holim'a moqolo ho bona boemo ba ho sebetsa ha mochini.

Li-parameter tsa Tekheniki

| Mohlala | FH18-52ZD-200 | FH18-52ZD-260 | FH18-52ZD-320 |

| Sekhahla sa ho tjheseletsa sa liner | 6-26m/motsotso | 10-26m/motsotso | 10-36m/motsotso |

| Bokgoni ba Tlhahiso | 100-200makoti/motsotso | 30-120makoti/motsotso | 30-100makoti/motsotso |

| Mefuta e fapaneng ea bophara ba can | 52-99mm | ||

| Sebaka sa Bophahamo ba Kane | 55-200mm | 70-280mm | 70-320mm |

| Thepa | Poleiti ea tinplate/tšepe/chrome | ||

| Tinplate Botenya Range | 0.16-0.3mm | ||

| thepa e sebetsang | 1.38mm 1.5mm | ||

| Metsi a Pholileng | Mocheso:<=20℃ Khatello:0.4-0.5MpaHo ntsha metsi:10L/min | ||

| Phepelo ea motlakase | 380V±5% 50Hz | ||

| Matla a Feletseng | 63KVA | 40KVA | 40KVA |

| Litekanyo tsa Mochini | 1750*1100*1800 | ||

Ka boiphihlelo ba lilemo tse fetang 17 mabapi le ho etsa mak'hane, re khona ho fa bareki likeletso tsa boenjiniere le ho thusa bareki ho fumana lihlahisoa tse tšoanelehang le litharollo tse ntle bakeng sa merero ea bona.

Ka kopoiteanye le ronabakeng sa Litharollo tsa Hao tsa ho Etsa Mehala ea Kantle ka Othomathiki