Karolo ea Mochini o tsoetseng pele oa ho Welding le oa ho Slitting ho Tin Can Manufacturing

Lipaketeng tsa lijo le lino, makotikoti a ntse a tsoela pele ho ba ntho e ka sehloohong ka lebaka la ho tšoarella ha ona, ho baballa litšenyehelo, le bokhoni ba ho boloka likahare. Leha ho le joalo, ts'ebetso ea ho etsa makotikoti ana e fetohile haholo ho theosa le lilemo, 'me tsoelo-pele ea theknoloji e etsa hore tlhahiso e sebetse hantle le e nepahetseng. Bohareng ba tlhahiso ea tin ea sejoale-joale ho na le lisebelisoa tsa bohlokoa joalo ka mechini ea othomathike ea ho cheselletsa 'mele, lithipa tse sehang tsa tinplate, le mechini ea othomathike ea ho poma, e netefatsang sehlahisoa se felileng sa boleng bo holimo.

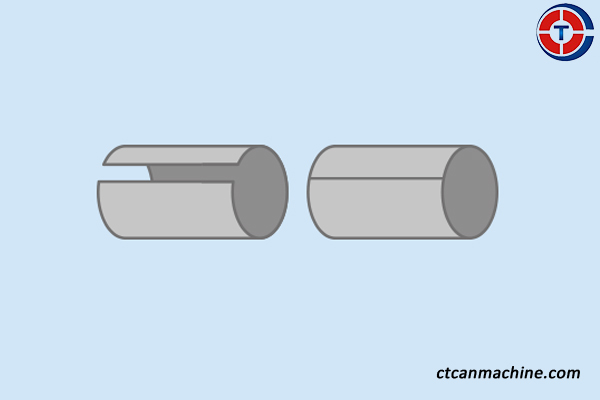

E 'ngoe ea lintlafatso tsa bohlokoahali molemong oa tlhahiso ea tin can ke mochini o tjheseletsang 'mele oa othomathike. Mechini ena e bapala karolo ea bohlokoa ho hokahaneng le 'mele oa cylindrical oa lekotikoti ka ho tjheseletsa seams tsa tšepe, hangata e sebelisa lisebelisoa tse kang tinplate, tšepe, poleiti ea chrome, poleiti ea galvanized le tšepe e sa hloekang. Mechini ea sejoale-joale ea tjheseletsa e tsoang ho bahlahisi ba kang Changtai Intelligent e etselitsoe ho potlaka le ho nepahala, ho eketsa ts'ebetso le ho fokotsa menyetla ea liphoso. Mechini ena e etselitsoe ho cheselletsa seams ka nepo e phahameng, e leng ntho ea bohlokoa ho netefatsa boleng ba sebopeho sa can.

melemo ea bohlokoa

Themochini o tjheseletsang mmele ka othomathikee fana ka melemo e mengata ea bohlokoa e etsang hore e be karolo ea bohlokoa ea lisebelisoa tsa ho etsa likoti tsa sejoale-joale:

● Ho Eketseha Lebelo la Tlhahiso: Mechini ea welding e iketsang e fokotsa haholo nako e hlokahalang ea ho kopanya maqephe a tšepe, e eketsa lebelo la kakaretso la ts'ebetso ea tlhahiso. Sena se nolofalletsa bahlahisi ho hlahisa meqomo e meholo ea makotikoti ka nako e khuts'oane, ho ntlafatsa ts'ebetso le ho fihlela tlhoko e phahameng.

● Ho Hlokahala ho Holimo le ho Tšepahala: Mechini ena e etselitsoe ho cheseletsa ka nepo litšepe tsa seam, ho etsa bonnete ba hore makotikoti 'ohle a cheseha ka mokhoa o tsitsitseng le o tšoanang. Ho nepahala ha mechini ea othomathike ea tjheseletsa ho thusa ho tlosa mefokolo joalo ka seams tse fokolang kapa tse sa lekaneng, tse ka senyang botsitso ba sebopeho sa makotikoti.

● Litšenyehelo tse Fokotsoeng tsa Basebetsi: Kaha mokhoa ona o ikemela, tlhokahalo ea mosebetsi oa matsoho e fokotsehile haholo. Sena ha se fokotse litšenyehelo tsa basebetsi feela empa se boetse se fokotsa liphoso tsa batho, e leng se lebisang ho boleng bo tsitsitseng ba tlhahiso. Basebelisi ba hloka feela ho beha leihlo mochini, e leng ho fokotsang kotsi ea liphoso le likotsi.

● Matla a Matla: Mechini ea sejoale-joale ea tjheseletsa hangata e entsoe ka likarolo tse bolokang matla tse ntlafatsang tšebeliso ea matla nakong ea ts'ebetso ea welding. Sena se fokotsa litšenyehelo tsa ts'ebetso mme se kenya letsoho mekhoeng e tsitsitseng ea tlhahiso.

● Taolo ea Boleng e Ntlafetseng: Ka likarolo tse tsoetseng pele tse kang mekhoa ea ho hlahloba le ho laola seam e ikemetseng, mechine ena e khona ho lemoha mefokolo nakong ea tlhahiso, ho netefatsa hore makotikoti feela a finyellang litekanyetso tsa boleng a fetela mohatong o latelang oa ts'ebetso. Tlhokomelo ena e tsoelang pele e ntlafatsa boleng ba kakaretso ea sehlahisoa se felileng.

● Litšenyehelo tse Tlase tsa Tlhokomelo: Mechini e mengata ea ho tjheseletsa ka othomathike e hahiloe ka likarolo tse tšoarellang, tsa boleng bo holimo tse hlokang ho hlokomeloa khafetsa ha li bapisoa le mefuta ea khale, ea matsoho. Litlhahlobo tsa kamehla tsa boiketsetso li boetse li thusa ho tseba mathata a ka bang teng pele a lebisa ho theoheng kapa ho lokisoa ho theko e boima.

● Ho Kopana le Lisebelisoa tse ling: Mechini ena ea ho cheselletsa e ka kopanngoa ka mokhoa o sa tsitsang moleng oa tlhahiso o ikemetseng, o sebetsa hammoho le mechine e meng e kang mechine ea ho petsola, mechine ea ho kuta le lisebelisoa tsa ho roala. Sena se theha mokhoa o bonolo, o sebetsang hantle oa tlhahiso o fokotsang mathata le ho ntlafatsa tlhahiso.

● Flexibility for Customization: Mechini e mengata ea othomathike ea li-welding tsa 'mele e ka fetoloa hore e lumellane le boholo le litlhaloso tse fapaneng. Ho feto-fetoha ha maemo ho etsa hore ho be bonolo ho hlophisa tlhahiso ea lihlahisoa ho fihlela litlhoko tse khethehileng tsa mmaraka, ebang ke bakeng sa lihlahisoa tse nyenyane kapa tse kholo.

Mechini ea li-welding ea 'mele e ikemetseng e fana ka melemo e mengata e ntlafatsang ts'ebetso, e fokotsang litšenyehelo, le ho ntlafatsa boleng ba sehlahisoa, e leng se etsang hore e be karolo ea bohlokoa tlhahisong ea sejoale-joale.

Ka mor'a ts'ebetso ea ho cheselletsa, lipampiri tsa tšepe li behoa tlas'a slitting ho hlahisa lihlopha tse fokolang tse tla theha 'mele oa cylindrical. Lithipa tsa tinplate li bohlokoa mohatong ona, ho seha lishiti tsa tšepe ka nepo e nepahetseng. Boleng ba lithipa tsena, tse atisang ho etsoa ka thepa ea boleng bo phahameng joaloka carbide, e ama ka ho toba ho nepahala ha mokhoa oa ho betla le boleng ba kakaretso ba 'mele ea likoti. Likhamphani tse kang Huxin Cemented Carbide li ikhethela ho hlahisa li-blade tsena tsa carbide, tse tsejoang ka bohale ba tsona, ho se mamelle, le nako e telele ea bophelo.

Ka kopanelo, mahlale ana a nolofatsa ts'ebetso ea tlhahiso ea tin can, e lumella bahlahisi ho hlahisa makotikoti a boleng bo holimo ka lebelo le potlakileng. Ha tlhoko ea bareki ea liphutheloana tse tšepahalang le tse tšoarellang e ntse e hola, indasteri e ntse e tsoela pele ho tsetela ho mechini e tsoetseng pele e netefatsang katleho le ho nepahala. Ho tloha ho tjheseletsa ho isa ho ho seha le ho poma, tshebediso ya thepa e tsoetseng pele ya ho etsa makotikoti e bula tsela bakeng sa mehla e mecha ya ditharollo tsa ho paka.

China e etellang pele mofani oaLikotoana tse 3 Mochini oa ho Etsa LikotikotileMochini oa ho Etsa Aerosol.

Changtai Intelligent Equipment Co., Ltd.Ke setsebi se nang le phihlelo se nang le phihlelo ea ho etsa mochini oa mochine. Ho kenyelletsa ho arohana, ho bōpa, ho roka melala, ho phunya, ho roka le ho roka, mekhoa ea rona ea ho etsa litsamaiso e na le maemo a holimo le bokhoni ba ts'ebetso 'me e loketse mefuta e mengata ea likopo,

Ka mokhoa o potlakileng, o bonolo oa ho lokisa lisebelisoa, li kopanya tlhahiso e phahameng ka ho fetesisa le boleng ba sehlahisoa se holimo, ha li ntse li fana ka maemo a phahameng a polokeho le ts'ireletso e sebetsang bakeng sa basebelisi.

Tseba ho feta

Ho tseba haholoanyane ka litheko le litšebeletso, ka kopo, tlanya mona >>>Iteanye le rona

--------

Ho tseba haholoanyane ka Khamphani ea rona, ka kopo tlanya mona >>>Mabapi le rona

--------

Ho tseba haholoanyane ka potefolio ea rona, ka kopo, tlanya mona>>>Lihlahisoa tsa rona

--------

Ho tseba haholoanyane ka AfterSales ea rona le Batho ba bang le bona ba botsa lipotso, ka kopo tlanya mona>>>LBH

--------

Sheba lihlahisoa > > >Khokahano: E ka etsa lisebelisoa ...

Nako ea poso: Jun-12-2025